Rutile type electrode depositing Radiographic welds for structurals.

It is a medium coated all position rutile electrode. Radiographic welds are eminently suitable for structural jobs. Mn to C Ratio as also Mn to Si ratio enhance mechanical properties, without any hot/cold cracking. Autoslag release alongwith finely rippled welds make it welder-friendly. Smoke and spatter are negligible

Welds at low ocv in AC transformer

Striking and Restriking are good

Absence of pungent and irritant fumes

Versatile type for general fabrications

| C | Mn | Si | S | P |

|---|---|---|---|---|

| 0.08 max | 0.38 to 0.60 | 0.24 max | 0.02 max | 0.02 max |

| Yield Strength | 350 N/sqmm (min) |

|---|---|

| U.T.S. | 410 N/sqmm (min) |

| %El (L = 5d) | 22(min) |

| CVN at 0º C | 50J |

| 2.5 mm | 50-80 amps |

|---|---|

| 3.15 mm | 90-130 amps |

| 4.0 mm | 140-190 amps |

| 5.0 mm | 180-240 amps |

Rutile type electrode depositing Radiographic welds for structurals

AWS SFA 5.11 E 6013

IS ER 4211

It is a medium coated all position rutile electrode. Radiographic welds are eminently suitable for structural jobs. Mn to C Ratio as also Mn to Si ratio enhance mechanical properties, without any hot/cold cracking. Autoslag release alongwith finely rippled welds make it welder-friendly. Smoke and spatter are negligible.

Welds at low ocv in AC transformer

Striking and Restriking are good

Absence of pungent and irritant fumes

Versatile type for general fabrications

| C | : | 0.08 max |

|---|---|---|

| Mn | : | 0.38 to 0.60 |

| Si | : | 0.24 max |

| S | : | 0.02 max |

| P | : | 0.02 max |

| Yield Strength | 350 N/sqmm (min) |

|---|---|

| U.T.S. | 410 N/sqmm (min) |

| %El (L = 5d) | 22(min) |

| CVN at 0º C | 50J |

| 2.5 mm | 50-80 amps |

|---|---|

| 3.15 mm | 90-130 amps |

| 4.0 mm | 140-190 amps |

| 5.0 mm | 180-240 amps |

Rutile type electrode depositing Radiographic welds for structurals.

It is a medium coated all position rutile electrode. Radiographic welds are eminently suitable for structural jobs. Mn to C Ratio as also Mn to Si ratio enhance mechanical properties, without any hot/cold cracking. Autoslag release alongwith finely rippled welds make it welder-friendly. Smoke and spatter are negligible

Welds at low ocv in AC transformer

Striking and Restriking are good

Absence of pungent and irritant fumes

Versatile type for general fabrications

| C | Mn | Si | S | P |

|---|---|---|---|---|

| 0.08 max | 0.38 to 0.60 | 0.24 max | 0.02 max | 0.02 max |

| Yield Strength | 350 N/sqmm (min) |

|---|---|

| U.T.S. | 410 N/sqmm (min) |

| %El (L = 5d) | 22(min) |

| CVN at 0º C | 50J |

| 2.5 mm | 50-80 amps |

|---|---|

| 3.15 mm | 90-130 amps |

| 4.0 mm | 140-190 amps |

| 5.0 mm | 180-240 amps |

Rutile type electrode depositing Radiographic welds for structurals

AWS SFA 5.11 E 6013

IS ER 4211

It is a medium coated all position rutile electrode. Radiographic welds are eminently suitable for structural jobs. Mn to C Ratio as also Mn to Si ratio enhance mechanical properties, without any hot/cold cracking. Autoslag release alongwith finely rippled welds make it welder-friendly. Smoke and spatter are negligible.

Welds at low ocv in AC transformer

Striking and Restriking are good

Absence of pungent and irritant fumes

Versatile type for general fabrications

| C | : | 0.08 max |

|---|---|---|

| Mn | : | 0.38 to 0.60 |

| Si | : | 0.24 max |

| S | : | 0.02 max |

| P | : | 0.02 max |

| Yield Strength | 350 N/sqmm (min) |

|---|---|

| U.T.S. | 410 N/sqmm (min) |

| %El (L = 5d) | 22(min) |

| CVN at 0º C | 50J |

| 2.5 mm | 50-80 amps |

|---|---|

| 3.15 mm | 90-130 amps |

| 4.0 mm | 140-190 amps |

| 5.0 mm | 180-240 amps |

Standard : AWS sfa 5.1 E 7016

A medium heavy coated all-position, extra low hydrogen electrode. It resists hydrogen-induced embrittlement. Hardenable steels and high sulphur steels can be welded. Welding needs no Stress Relief.

Weldable in all positions, with quiet arc and low spatter. Smooth flow, easy slag detachability, finely rippled bead surface.

| Yield strength (N/mm²) |

Tensile strength (N/mm²) |

Elongation (l = 5d)% |

V notch impact Strength @ -30 C (Joule) |

|---|---|---|---|

| 450 | 565 | 24.2 | 94 |

| C | 0.06 |

|---|---|

| Mn | 1.15 |

| Si | 0.6 |

| S | 0.016 |

| P | 0.019 |

Radiographic quality Grade 1

Diffusible hydrogen 3.1 ml per 100 g weld metal

Clean the weld zone and degrease. Keep the arc short. Weld with stringer beads. Use only dry electrodes.

Current type: AC/DC(+)

| Electrodes | Ø mm | 2.50 | 3.15 | 4 | 5 |

|---|---|---|---|---|---|

| Amperage | A | 60-70 | 100-140 | 130-190 | 150-160 |

Standard : AWS sfa 5.1 E 7018

A medium heavy coated all-position, extra low hydrogen iron powder type electrode. It resists hydrogen-induced embrittlement. High strength radiographic quality welds on mild steels, medium carbon and ASTM 516 Gr A are possible. Deposition efficiency 115 % approx. Drying at 250°C for 1 hour before welding recommended.

Weldable in all positions except vertical down. Smooth flow, easy slag detachability, finely rippled bead surface. Bright and shiny beads

| Yield strength (N/mm²) |

Tensile strength (N/mm²) |

Elongation (l = 5d)% |

V notch impact Strength @ -30 C (Joule) |

|---|---|---|---|

| 450 | 565 | 24.2 | 94 |

| C | 0.06 |

|---|---|

| Mn | 1.15 |

| Si | 0.6 |

| S | 0.016 |

| P | 0.019 |

Radiographic quality Grade 1

Diffusible hydrogen 3.1 ml per 100 g weld metal

Clean the weld zone and degrease. Keep the arc short. Weld with stringer beads of weaves slightly. Use only dry electrodes.

Current type: AC/DC(+)

| Electrodes | Ø mm | 2.50 | 3.15 | 4 | 5 |

|---|---|---|---|---|---|

| Amperage | A | 60-70 | 80-100 | 130-150 | 150-160 |

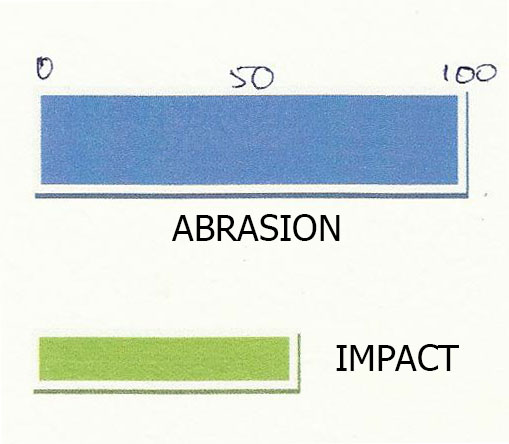

AIR HARDENING WELDMENT FOR BUILD UP METAL TO METAL WEAR, RESISTING MODERATE FRICTION AND ROLLING SCOUR

BUILD UP ON CARBON STEELS IS FACILITATED DUE TO HIGH STRENGTH WELDMENTS. IT ENABLES BUFFER/CUSHIONING FOR HARDFACING OVERLAYS IT ALSO RESTORES ORIGINAL DIMENSIONS BY MULTILAYERING IT HAS GOOD COMPRESSIVE STRENGTH THEREBY ABSORBING HEAVY IMPACT IT IS MACHINABLE MANGANESE STEELS OR CAST IRONS ARE AVOIDED JOINING IS NOT RECOMMENDED.

IT IS SUITABLE FOR RESISTING FRICTIONAL WEAR AS ALSO ROLLING SCOUR.

| C | : | 0.15 |

|---|---|---|

| Cr | : | 0.4-0.8 |

| Mo | : | 1-1.5 |

| Mn | : | 0.1-0.3 |

| Si | : | 0.2 |

GOUGING/CUTTING/GRINDING IS DONE TO REMOVE FATIGUED /WORN OUT SURFACE. STRINGER BEADS ENABLE SUPERIOR SURFACE MODIFICATION

FERRITIC

| SIZE (MM) | 4.0 | 5.0 |

|---|---|---|

| CURRENT (AMPS) | 130-170 | 150-190 |

| CURRENT TYPE | AC/DC(+) |

Basic coated electrode for frictional and compressive wear.

It is a basic coated electrode combating wear due to friction and compression. Alloy chemistry enables welds with multilayer welding. It is so formulated to produce extra low hydrogen without any underbead cracking. Low spatter and thick deposits are of radiographic quality welds.

Reclamation of worn-out points, rollers, equalizer beams, guide rolls and others.

| C | : | 0.05 |

|---|---|---|

| Cr | : | 6-8 |

| Mo | : | 0.7 |

| V | : | 0.6 |

| Mn | : | 0.3 |

| Si | : | 0.3 |

| Hardness | 350 | 450 | BHN |

|---|---|---|---|

| Diameter | 3.15 | 4.0 | 5.0 |

| Current | 100-120 | 130-150 | 160-180 |

600B

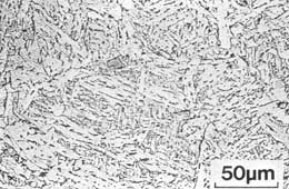

Martensitic weldments resisting wet and dry abrasion with moderate impact

Allow chemistry CMn Si Cr MoV

Basic low hydrogen type weldments are martensitic type, with fine, evenly dispersed Cr-Mo-V carbides. Thick, dense beads are radiographic and crack-free enabling 3-layer deposits. All position welding with good slag detachability on low-, medium-, and high- carbon steels makes it welder-friendly. It is eminently suitable for wet (soil) and dry abrasion.

Plough shares, cutter blades, sprockets, augers, crusher rollers, mill rollers, screen conveyors, tillage machinery parts, agro parts and others

Wear-prone or fatigued surface is gouged or ground. Stringent beading in criss-cross or dot/dash pattern enhances wear resistance

| C | : | 0.5 |

|---|---|---|

| Mn | : | 1.0 |

| Si | : | 0.6 |

| Cr | : | 6.5 |

| Mo | : | 0.8 |

| V | : | 0.5 |

| Microstructure | martensite with Cr-Mo-V carbides finely dispersed | ||

|---|---|---|---|

| Hardness | 57-62 HRc | ||

| Welding Data (AC/DC(+)) Size(mm) |

3.2 | 4.0 | 5.0 |

| Current(amps) | 90-160 | 120-180 | 160-220 |

UTS - (585-615)

Welding Cast Iron Parts (Non-Machinable), Building up Machine frames, repair of foundry casting, Gear Boxes, Differential Housing, Sugar mill rollers, Cast Iron dies.

UTS - (400-510)

Elongation L=40

177 (BHN) Approx

Welding Cast Iron Parts (Machinable), Heavy foundry casting, Automobile Engine blocks & heavy casting machinery parts, Can be used on Casting containg Phosphorus level higher than normal upto 0.2%

UTS - (280-400)

Elongation L=40

140-160 (BHN)

Welding for Fracture and heavy castings, fabricating Cast iron machine Components, rebuildings worn-out surfaces.

| C | : | 0.80 |

|---|---|---|

| Mn | : | 1.00 |

| Si | : | 0.60 |

| S | : | 0.03 |

| P | : | 0.03 |

| Mo | : | 65.0 |

AWS SFA:5.4 E308L-16

Corrosion resisting Cr-Ni austenitic stainless steel electrode

Specially formulated coating gives dense, pore-free, radiographic quality welds in all positions. Smooth, low spatter, negligible smoke and bright shiny .Slag detaches easily.

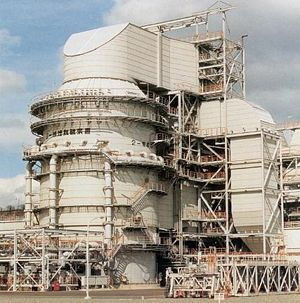

Extra low carbon content ensures no risk of weld decay ie carbide precipitation is reduced. It is applied where operating temperature is upto 350 C AISI 301, 302, 304, 304L, 308 and 308L. Dairy, foodstuff, chemical industries and fertilizer plants parts and components of similar.

| C | : | 0.039 |

|---|---|---|

| Mn | : | 1.30 |

| Si | : | 0.47 |

| Cr | : | 19.28 |

| Ni | : | 9.47 |

| S | : | 0.008 |

| P | : | 0.024 |

| UTS N/sqmm | 530 | % El | 35 (min) | FN | 3-8 |

| SIZE (MM) | 2.5 | 3.15 | 4.0 |

|---|---|---|---|

| Current(amps) | 40-70 | 80-110 | 120-160 |

AWS SFA:5.4 E309L-16

AUSTENITIC RESISTING CORROSION AND THERMAL WEAR

ELECTRODE DEPOSITS THICK SMOOTH BEADS. SLAG REMOVAL IS EASY. FREE OF PORES, IT GIVES STABLE ARC

REBUILDING AND BUFFERING BEFORE HARDFACING DISSIMILAR WELDS BETWEEN C-Mn AND LOW ALLOY STEELS

THERMAL WEAR RESISTANCE UPTO 1000 C IS POSSIBLE

| C | : | 0.02 |

|---|---|---|

| Mn | : | 1.1 |

| Si | : | 0.6 |

| Cr | : | 23.5 |

| Ni | : | 13 |

| FN | : | 12 |

| Y S | 470 MPa | U T S | 570 MPa | %El | 37 |

| SIZE (MM) | 2.5 | 3.15 | 4.0 |

|---|---|---|---|

| Current(amps) | 40-70 | 80-110 | 120-160 |

AWS A5.4 E310-16

Thermal Resisting Cr-Ni Austenitic Stainless Steel Electrode

It is used for combating thermal wear, avoiding deformation of parts. It is stable at elevated temperatures, resisting hot cracking, due to NIL ferrite.

The Alloy-rich welding finds applications in welding furnace components, heat treatment parts, burners and nozzles

Grease oil and others are removed . Avoid weaving. Using lowest possible amps, maintain short arcs.

| C | : | 0.09 |

|---|---|---|

| Mn | : | 1.85 |

| Si | : | 0.55 |

| Cr | : | 26.1 |

| Ni | : | 20.9 |

| Y.S | 420 N/sqmm | U.T.S | 540 N/sqmm | %El | 35 |

| SIZE (MM) | 3.15 | 4.0 |

|---|---|---|

| Current(amps) | 40-70 | 120-160 |

AWS SFA:5.4: E316L-16

Dense thick welds are of radiographic quality. Flux is so formulated to please the welder so also the metallurgist alike. Soft fusion and less spatter in all positions characterize the weld. Slag removal is easy with good arc striking and restriking.

It is a lime-titania type electrode with a good weldability. As the all-weld metal has an austenite structure having adequate ferrite, crack resistance is excellent. It resists intergranular corrosion due to carbide precipitation in the as-welded condition since carbon content is less Service temperature ranges from -120 C to + 350 C.

It finds extensive applications in nuclear reactor, chem., petrochem, pharma food and beverages and dairy, paper and fertilizer industries.

Grease, Oil and others are cleaned. Weaving is avoided. Medium current and short arc result in strong and ductile welds.

Austenite with a little ferrite (FN 8)

| SIZE (MM) | 3.15 | 4.0 | 5.0 |

|---|---|---|---|

| Current(amps) | 70-110 | 120-160 | 140-180 |

| Tensile Strength | 540 N/sqmm | ||

| Yield Strength | 320 N/sqmm | ||

| Elongation | 35% |

Identification : Name printed on Coating Cutting electrode

It is suitable for cutting, chamfering and piercing all industrial metals.

It strikes easily and achieves clean cuts even on thicker materials, in view of its high current – carrying capacity.

Set up the workpiece so that the molten metal can run off easily. It is advisable to execute an up-and-down sawing movement, pushing the molten metal away with the electrode. Depending on the electrode diameter and material thickness, the amperage is varied between the limits indicated below.

Current type dc (straight polarity) or ac

| Electrodes | Ø mm | 2.5 | 3.15 | 4 | 5 |

|---|---|---|---|---|---|

| Amperage | A | 100-150 | 130-180 | 200-300 | 300-400 |